Atoco plans to commercialise its atmospheric water harvesting technology with a 20-foot containerised unit designed for industrial deployment.

Each on-grid unit is expected to produce around 2,000 to 4,000 litres of high-purity water per day while off-grid units can produce up to 1,000 litres a day.

This technology offers growers and operators a supplementary and decentralised water source in arid and semi-arid regions.

“As controlled environment agriculture and other industries face growing water challenges, we believe we can contribute to something meaningful through what we call water-positive greenhouses or water-positive indoor farming,” said Han Park, Product Market Specialist of Atoco.

“This is where the indoor farming and greenhouses can can self-sustain and self-create water by leveraging innovative technology from Atoco. I think the future is extremely bright and very encouraging for us as we look to partner with established market leaders.”

Park was speaking on a panel on Controlled Environment Agriculture (CEA) at the World Agri-Tech Innovation Summit Dubai in December.

Nobel Prize winning technology

Atoco was founded by chemist Omar Yaghi, who was recently awarded the 2025 Nobel Prize in Chemistry alongside Susumu Kitagawa, and Richard Robson.

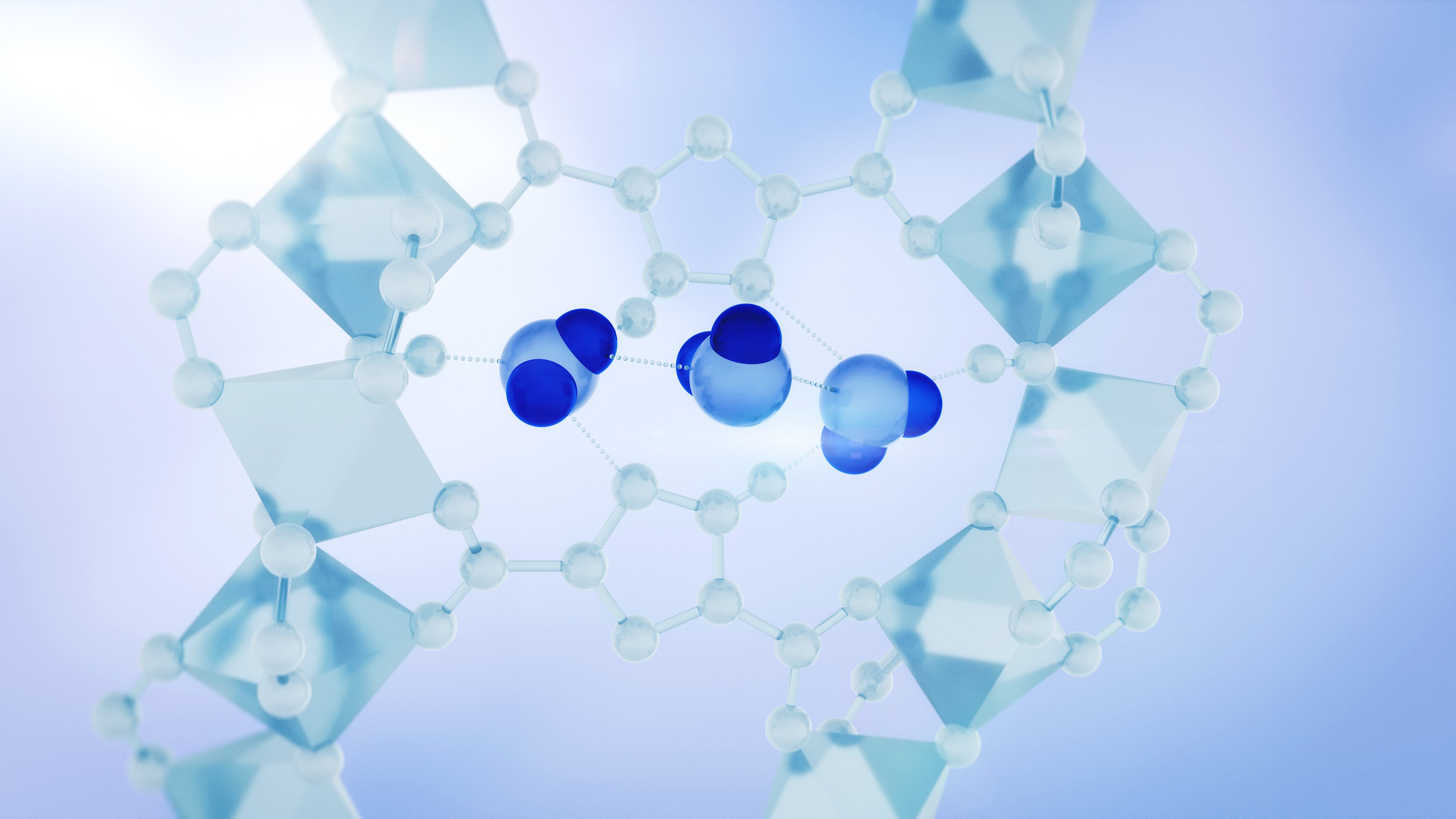

It relies on a reticular material, also known as a metal-organic framework (MOF), which has a highly porous structure capable of capturing water molecules from the air.

The company has tested the technology in the extremely dry conditions of Death Valley in California.

“It’s a solid substance which has a large porous space where it has a capability to really park and capture H2O molecules, even in arid regions. We tested the material in Death Valley National Park in California. It’s one of the driest, if not the driest, place on Earth, and we were able to harness the ambient energy to produce water, and the water that we generated was near distilled water quality,” said Park.

In addition to generating water, technology can support humidity and climate control by extracting moisture from the air inside greenhouses and indoor farms.

This helps reduce energy consumption, one of the most challenging issues for CEA, Park pointed out.

He stressed that while the system will not fully replace existing water sources, it can serve as a supplementary supply and diversify water sourcing.

A circular solution

The technology harnesses free ambient energy, providing a sustainable, energy-efficient solution, allowing it to operate off-grid.

Park described a vision in which greenhouses become “nodes” within a broader energy and water ecosystem, linking industrial waste heat with agricultural water production.

“We are seeing more vertical farms and indoor farms located near urban areas and industrial zones because of their demand for power and water. Our off-grid technology can harness low-grade waste heat from industrial power sources or even data centre servers, where this energy is typically dissipated and not utilised.

“By connecting the industrial sector with controlled environment agriculture, and looking beyond CEA alone, we can create a circular system in which industrial waste heat is captured by Atoco’s technology to produce high-purity water for greenhouses. In this way, greenhouses can become a node within a broader energy and water loop.”

As interest grows in non-conventional water sources, the company hopes atmospheric water can be more widely recognised alongside desalination and wastewater reuse, arguing that tapping moisture in the air could play a meaningful role in building more resilient and sustainable agricultural systems.

“Water is an essential part of our lives and the industry so being recognising atmospheric water as an alternative source of water would be critical for us to work together and create that synergistic effect with the CEA industry as a whole."