Changing concaves is a tedious process that can eat up a farmer’s precious time, requiring hours of manual labour. However, Canadian harvest optimisation company Bushel Plus is offering growers with John Deere X9 combines a solution to streamline this time-consuming problem with an after-market product.

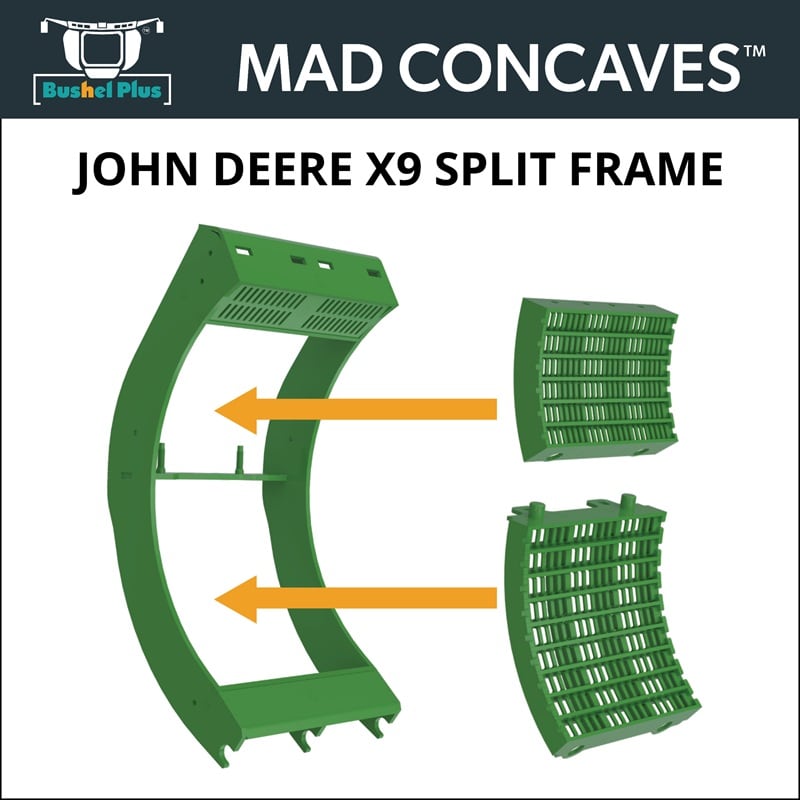

The X9 Split Frame MAD Concaves are purpose-built for John Deere X9 combines, providing farmers a modular way to change out the part, Marcel Kringe, founder and CEO of Bushel Plus, told AgTechNavigator.

Farmers can install the X9 Split Frame MAD Concaves within a couple of hours, and then they can change out two smaller modules within that frame, Kringe explained. Concaves are crucial parts of combine harvesters, as they “separate the grain from the straw and helps threshing, so that you get nice, clean grain samples,” he added.

“A lot of farmers switch concaves,” Kringe elaborated. “For example, if you do a wheat harvest or canola harvest, then you have to change concaves when you do soybeans or corn because the kernel size is so different.”

With the X9 Split Frame MAD Concaves, farmers “can switch the entire combine over from wheat to corn in 15 minutes with one person — four to five hours down to 15 minutes — without the need to recalibrate the concave clearance,” he explained.

Additionally, changing concaves is important to ensure a quality harvest, especially in the case of seed production, Kringe pointed out.

“[When] you have the right concave for the right crop, you get a better-quality threshing in the machine, which [produces] less cracked kernels, specifically in pulses. We have tested with a large seed farmer in Canada, and he had the best germination numbers he ever had in his soybeans because of our concaves,” he added.

Can after-market products help manage farming expenditures?

Growers across the globe are facing financial pressures, including rising ag machinery prices, creating an opportunity for after-market parts, Kringe noted.

U.S. farm expenditures (equipment, land, fertilisers, etc.) were estimated to be $477.6 billion in 2024, down slightly from a record $481.9 billion in 2023, according to the USDA’s 2025 Farm Production Expenditures Annual Summary. The Trump administration’s tariffs impacted ag machinery prices in 2025, with ag machinery companies, like AGCO and CNH Industrial, raising prices on parts and machines.

Farmers can extend the life and efficiency of their farm equipment with after-market parts, without needing to buy a new combine or piece of machinery, pushing back a major capital expenditure, Kringe said. Additionally, Bushel Plus’ concaves require less horsepower, which means farmers can save on fuel, he added.

“If you can add after-market parts to your combine and get more efficiency out of it and better threshing, then you may not need to buy a new combine right away. If you cannot buy one right now, here is the opportunity to get better efficiency out of a combine that has to stay on the farm for a bit,” he said.

Looking ahead to the rest of 2026, Bushel Plus is taking its parts and innovation on the road at several upcoming trade shows, including the Commodity Classic event in San Antonio, Texas, Feb 25-27. Additionally, Bushel Plus’ R&D, sales, and marketing teams continue to explore opportunities to launch new after-market products that address on-farm issues, Kringe said.

“If we can help one customer, that will help more than just this one person, because ... it is going to help them put more food in the food supply chain,” he stressed.