Agriculture leads growth in the global 3D printing market, with 87% of companies printing more parts than the previous year – exceeding the 70% average across all industries – according to a report by ProtoLabs, a digital manufacturer.

3D printing in agriculture is not just about maintaining machinery but also about enabling customized, efficient, and data-driven farming solutions, the report emphasised.

Major agricultural equipment manufacturers such as AGCO, John Deere, and Caterpillar are using 3D printing to customize their machinery and parts.

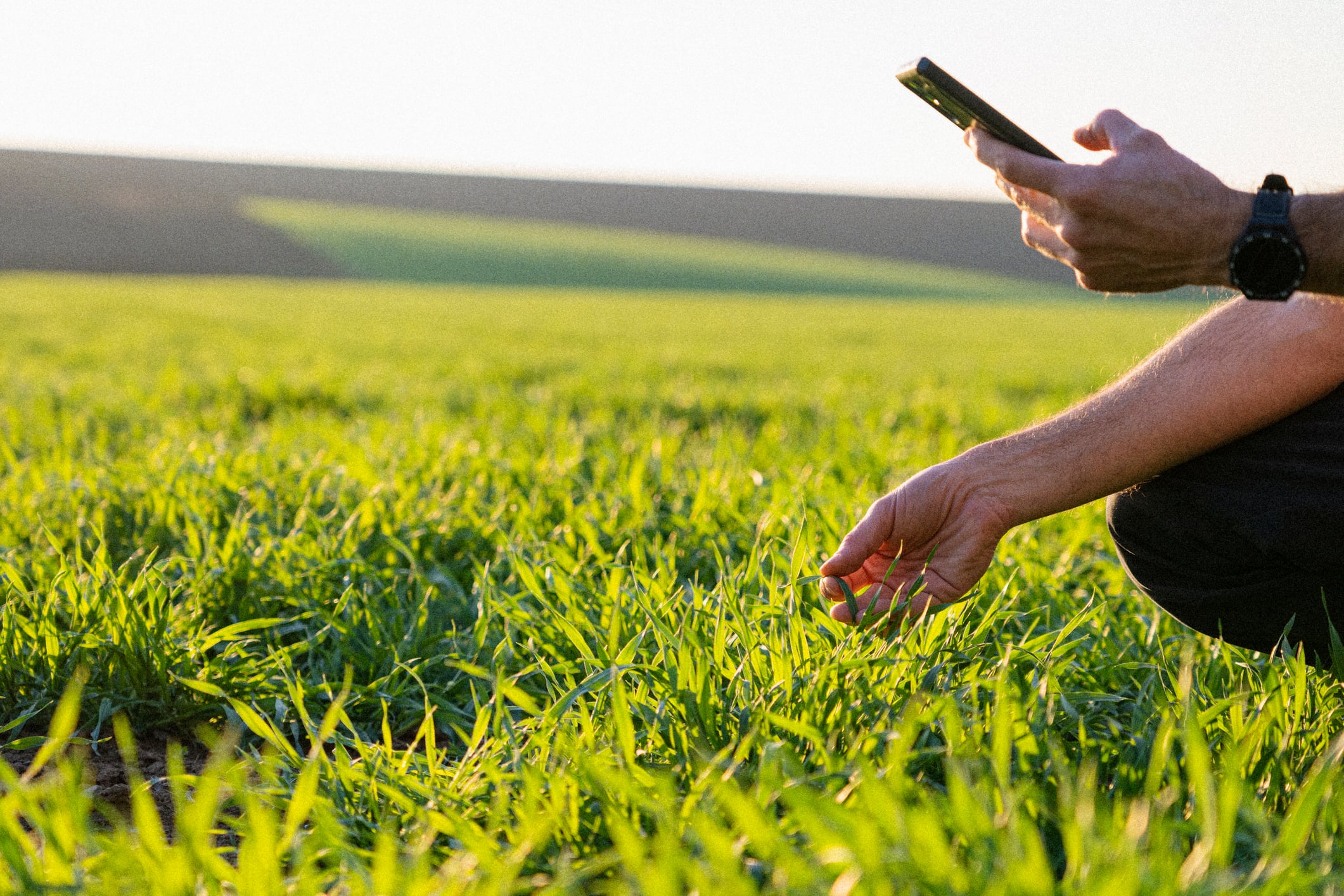

3D printing technology allows development of sensors that monitor crop health, soil moisture, and other key parameters, often integrated with AI-driven resource management systems in smart farming.

The rapid prototyping capability of 3D printing allows farmers to iteratively create and test bespoke tool designs, accelerating innovation on farms.

Other examples include custom irrigation components like sprinkler heads designed for specific chemicals and spray rates, bespoke connectors, and specialized crop handling tools such as grippers, planting and cutting tools, and sorting mechanisms.

What’s driving 3D printing in ag?

The rise is partly thanks to the “inventiveness” of opportunistic farmers, said Eric Utley, 3DP applications engineering manager at Protolabs.

“3D printing is used in a large range of applications like crop processing equipment, heavy machinery and irrigation management systems,” he told AgTechNavigator.

“It is particularly good at making complex shapes like spray nozzles and mixers that can be found in agricultural industrial equipment. I believe the increasing use of drones in agriculture is also contributing to the rise in use you see in the report.”

3D printing leaving a mark

Growth in the 3D printing sector as a whole is exceeding predictions.The market hit $12 billion in 2020 (nearly 4x the predicted $3.1 billion) and is projected to reach $57.1 billion by 2028 –figures that exceed what was originally predicted for 2050.

Falling costs and improved technologies are making 3D printing more accessible to small businesses and hobbyists, further fuelling adoption across sectors.

Further take up of 3D printing in agriculture is expected if costs should drop further, Utley told us.

“The main hurdle is that 3D printed components tend to be high value parts made in lower quantities than traditional manufacturing,” he said.

“This is why it is so heavily adopted in the medical and aerospace industries for things like surgical robots or satellites. These components are special, low volume, and high value and industrial farming equipment is traditionally simpler, high-volume products. The scalability of 3D printed components is also quite sensitive to part size. A 3D printed component the size of a golf ball much more scalable than a component the size of a basketball.”

3D printing in farming equipment is typically going to see the most benefit in specialized farming practices or around a specific crop that benefits from specialized equipment, Utley added. “It is also a good fit for ‘smart’ technology solutions because the hardware of those components tend to be updated on a much faster cycle than typical agricultural products and tend to be of a smaller form factor.”

IP issues expected to rise

Farmers are now printing spare parts directly on-site, slashing downtime and eliminating long waits for hard-to-source components, according to Susan Bradley, partner at UK-based global intellectual property firm Marks & Clerk.

The rise of metal and polymer 3D printing is enabling the production of durable, weather-resistant parts tailored for field conditions and remote operations, she said.

As digital manufacturing leaves a mounting impact on agriculture, she said new legal questions will mount, such as how do farmers and agri-tech businesses protect their digital files, software and hybrid material inventions.

Another barrier is users understanding of the technology.

“It’s fine to buy a 3d printer but you need to understand how to download the file that enables you to 3d print; what materials you are going to use how to maintain it.”